Certification of workwear and accessories

Learn more about certifications for workwear and accessories

Making sense of the European EN standards and certifications for workwear, knee pads and gloves might seem complicated, but failure to comply with them can lead to costly fines. We have compiled a list of the most important certifications to help you get informed and ensure that you choose the right workwear and equipment for the work you’ll be carrying out.

Certification of workwear

EN ISO 20471 (ex EN 471) - Visible, Hi-Vis clothing

EN ISO 20471 is the international standard for high visibility clothing, also called reflective or Hi-Vis clothing, and is the most common workwear certification. EN 20471 is the replacement for the previous EN 471 standard. The fluorescent colour makes you visible in daylight, with the reflectors ensuring you are also visible in the dark. This certification is required for work in high-risk areas, where you work near traffic, construction sites or generally near motorized vehicles, such as cranes and excavators. EN ISO 20471 is categorised into 3 classes based on the material’s surface visibility – the amount of fluorescent material and reflective material determines which safety class the clothing belongs to. Class 3 sets the highest requirements.

- EN ISO 20471-1 - minimum 0.14 m² fluorescent material and minimum 0.10 m² reflective material.

- EN ISO 20471-2 - minimum 0.50 m² fluorescent material and minimum 0.13 m² reflective material.

- EN ISO 20471-3 - minimum 0.80 m² fluorescent material and minimum 0.20 m² reflective material.

Class 3 clothing can be achieved in several ways. You can use a class 3 product or combine two class 2 products, which together become class 3 certified.

You can see the combination options in the table below:

|

EN ISO 20471 |

Class 3 |

Class 2 |

Class 1 |

|

Class 2 |

Total class 3 |

Total class 3 |

Total class 2 |

|

Class 1 |

Total class 3 |

Total class 2 |

Total class 1 |

EN ISO 11612 (ex EN 531) - Flame retardant workwear

EN ISO 11612 certified protective clothing protects the user from short-term contact with high heat and flames. The clothing is referred to as flame retardant or fire retardant in everyday speech. The clothing is classified according to various parameters, such as heat radiation, contact heat, etc. Workwear with the EN ISO 11612 certification is, among other things, suitable for electricians and industrial workers who may be at risk of exposure to fire or other hot environments. This certification is only used for clothing - with the exception of hoods. For the protection of the face or hands, additional protective equipment must be used.

See the selection of flame retardant workwear with EN ISO 11612 here.

| A1, A2 | Requirements for limited flame spread, A1: Surface ignition A2: Edge ignition |

| B (1-3) | Protection against convective heat and open flames |

| C (1-4) | Protection against radiant heat |

| D (1-3) | Protection against molten aluminium splash |

| E (1-3) | Protection against molten iron splash |

| F (1-3) | Protection against contact heat |

EN ISO 14116 (ex EN 533) - Flame retardant workwear (limited flame spread)

EN ISO 14116 certified protective clothing protects against brief, accidental contact with sparks or heat in circumstances where there is no significant heat risk and where there are no other types of heat. Workwear with EN ISO 14116 certification reduces the likelihood of ignition, which poses a safety risk.

If heat risk protection is required, EN ISO 11612 is recommended.

EN ISO 14116 is often used for clothing and accessories with a lower level of flame-retardant properties. This might be Hi-Vis vests, rainwear, knee pads, socks and more.

Class 3 is the highest level. Clothing under index 3 must be used in combination with clothing in accordance with EN ISO 11612. Index 1 clothing may not come into direct contact with the skin. That means it may only be worn on the outside of clothing of index 2 or 3.

See the selection of flame retardant workwear with EN ISO 14116 here.

| Index 1 |

Flame spread, flaming debris and afterglow properties |

| Index 2 | Flame spread, flaming debris and afterglow properties (Index 1) + hole formation properties |

| Index 3 | Flame spread, flaming debris and afterglow properties (Index 1) + hole formation properties (Index 2) + residual flame properties |

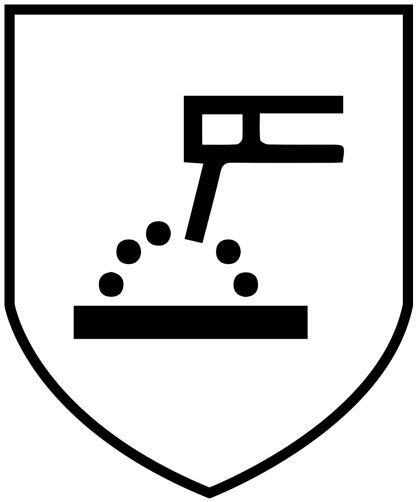

EN 13034 clothing for protection against liquid chemicals

This should be used when there is a risk of exposure to light fumes, liquid aerosols, small quantities of spray or accidental small splashes. EN 13034 protection is used when a complete barrier to liquid penetration is not required. Remove the work clothes immediately if you are exposed to chemicals.

Find workwear for protection against liquid chemicals with EN 13034 here.

| Chemical group | Chemical |

| Acid | H2S04-30% (sulphuric acid) |

| Base | NA0H 10% (sodium hydroxide - also known as lye or caustic soda) |

| Aromatic hydrocarbon | 0-xylene |

| Alcohol | Butanol |

IEC 61482-2

Clothing with this certification protects against thermal arc hazards of an electric arc. This means that the protective properties are designed to prevent the occurence of second-degree burns. The standard does not take into account other risks associated with arcs such as metal fragments, pressure waves, electric shocks and harmful gases that occur during the evaporation of the material.

The higher the calorific value of the material or clothing, the better it will protect the user. A test can also be performed on combinations of materials, thus achieving a higher protection value.

In 2019, a new safety clothing pictogram was added that meets the requirements of IEC 61482-2, which includes two test methods with different levels of risk:

IEC 61482-1-1 - Open Arc test

Involves a medium voltage range (> 1000 V)

Materials and clothing are exposed to an open arc during this test. Each material or combination of materials then achieves a result that is stated in terms of calorific value. The calorific value is the limit for the heat energy a material can be exposed to and still protect the user from second degree burns, the ATPV value, or for when holes appear in the material, the EBT value. ATPV and EBT are calculated on the basis of a 50% degree of protection.

ATPV and EBT were supplemented with an ELIM value in 2019. The idea behind ELIM is to eliminate the risk of a 2nd degree burn and help to protect the user safely - without increasing other risks or preventing the user from working.

IEC 61482-1-2 - Box test (directional arc)

Involves a low voltage range (400 V).

Material and clothing are tested against a direct arc at a certain value, and with a voltage of 400 V over a time period of 500 ms. The test is conducted in two different classes. Upon completion of the test, the result will be approved or not approved. Often, a combination of lined clothing or varied clothing is required to pass the class 2 Box test.

| Arch | Time | |

| Class 1/APC1 | 4kA - 168 kJ (400 V) | 500 ms |

| Class 2/APC2 | 7kA - 320 kJ (400 V) | 500 ms |

EN ISO 11611 (ex EN 470-1) - Workwear for welding

Protective clothing certified in accordance with EN ISO 11611 is intended for those who may come into brief contact with flames, work in welding or carry out similar work with similar risks. If the welding clothing is soiled with flammable substances, the flame-retardant effect is reduced. In addition, the welding clothing must be used along with other EN ISO 11611 certified clothing in order for the wearer to be fully protected. EN ISO 11611 is categorised into 2 classes:

- EN ISO 11611-1 - protects against less hazardous welding methods and situations in which lesser amounts of splashing and radiant heat may occur.

- EN ISO 11611-2 - protects against more hazardous welding methods and situations in which larger amounts of splashing and radiant heat may occur.

See the selection of workwear for welding with EN ISO 11611 here.

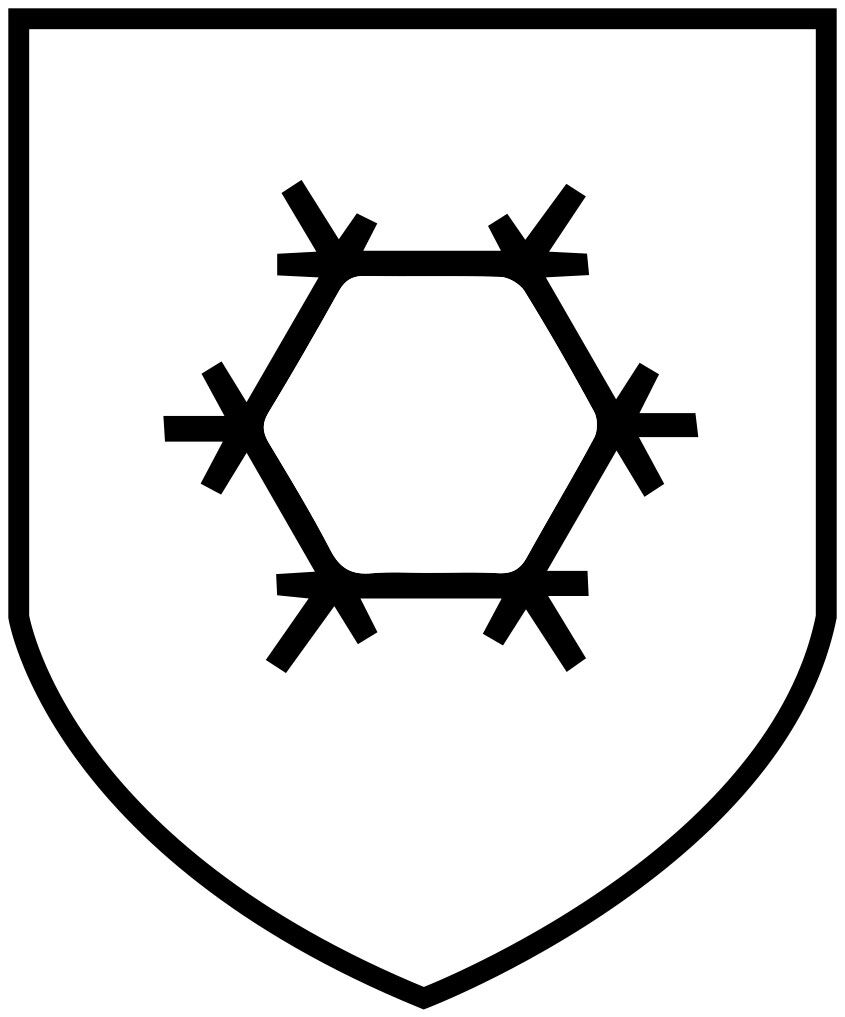

EN 342 - Cold

Protective clothing certified EN 342 protects you from cold. Cold is considered to be a combination of humidity and wind with an air temperature of below -5 ° C, where it is important to keep dry and warm. If the clothing gets wet, the properties are impaired. If there is a lot of wind, you may need more insulation, even if the temperature is unchanged. The protective qualities of the clothing can be impaired if the clothes are wet, so it is important to keep the clothes dry. Clothing for cover the hands, feet and head are needed to prevent localised cooling, which also provides better protection against cold. Make sure the clothing is zipped up and properly tightened around the wrists.

See the selection of workwear specifically designed for cold weather conditions here.

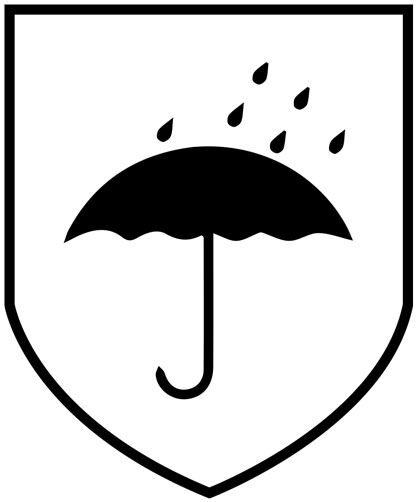

EN 343 - Rain

Protective clothing certified EN 343 protects you from snow, rain, fog and humid weather. EN 343 workwear has been tested for waterproofness class 1-4 and breathability class 1-4, of which class 4 is the highest level. The clothing’s breathability will usually reach a grade 4: 4 if it is unlined. If the clothing is lined, it is typically graded 4: 2.

Please be aware that the clothing must be carefully fastened in order to achieve the maximum protective effect, and that clothing with this certification is not suitable for work with fire.

EN 1149 3/5 - Electrostatic properties

These certifications protect you from electrostatic discharge - for example, for work where there is a risk of explosion hazard. When using clothing with these certifications, the user must be properly grounded and use proper footwear. Here, ensure that the clothing is covering the wearer during movement - for example, when kneeling.

- EN 1149-3: 2004 - electrical discharge

- The standard describes the decay of electrostatic charge from the surface of the clothing material.

- EN 1149-5: 2008 - material performance and design. The standard describes the requirements for materials and construction of electrostatic conductive protective clothing used in areas at risk of sudden electrostatic charges.

Protective clothing certified in accordance with EN 1149 protects the user from static electricity and reduces the risk of sparks. The clothing should be used as part of an overall grounded system to avoid electrostatic charges.

See the selection of workwear with electrostatic properties here.

EN 13758-2 - Workwear with UV protection

Clothing certified with EN 13758-2 protect you from the sun's UVA and UVB rays. If you work outside, you are at high risk of being exposed to the sun's rays, which can result in skin damage. The risk of skin damage can be reduced by wearing clothing with the EN 13758-2 certification. Please be aware that only skin that is covered by the clothing is protected.

Find a detailed explanation on the blog "Protect yourself from the sun with UV clothing".

EN ISO 15797 - Industrial washing

Clothes certified with EN ISO 15797 require that the product be suitable for industrial washing and industrial drying.

EN 381-5 - Workwear for work with chainsaws

EN 381-5 is the standard for protective clothing with saw and leg protection, also known as chainsaw trousers. If you work with forestry and logging, you need workwear with this certification.EN 381-5 is categorised by chain speed:

- Class 1 - protects at a chain speed of 20 m/s

- Class 2 - protects at a chain speed of 24 m/s

- Class 3 - protects at a chain speed of 28 m/s

Ensure that the trousers’ saw protectors overlap your protective footwear, otherwise you run the risk of not being optimally protected.

Oeko-tex® Standard 100 - the workwear has been tested for harmful substances

If you buy workwear with the Oeko-tex® Standard 100 certification, often simply referred to as Oeko-tex®, you are assured that your clothing has been tested for harmful substances. This is an international standard that imposes strict requirements on the products. It is not just the fabric that is tested, but all parts of the product, such as labels, zippers and filler materials.

Accessories

EN 397 - Industrial safety helmets

EN 397 is the certification for industrial safety helmets and therefore lives up to the physical requirements for material, construction and size. This certification has to protect the user from falling objects. Pay particular attention to the fact that safety helmets have an expiry date and are not approved after the expiry of the certification.

See our full range of safety helmets here.

In the text "Use your head with a safety helmet", you can read much more about tests and approval of helmets.

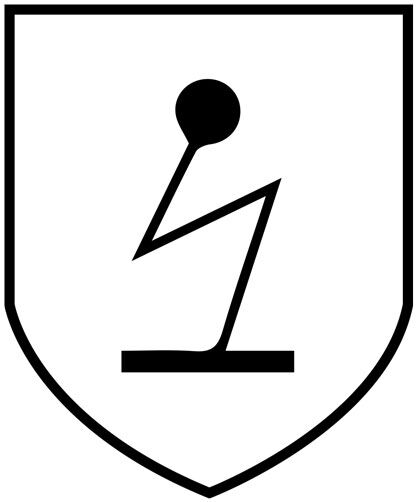

EN 14404 - Knee protection

If you need to use knee protectors for your work, look for the EN 14404 certification, which sets requirements for knee protectors for work in a kneeling position. Knee pads should be changed regularly as needed, as wear will degrade the quality. The EN 14404 certification is categorised into 3 levels, 0-2:

- Level 0 - Suitable for use on flat surfaces

- Level 1 - Suitable for use on flat or uneven surfaces

- Level 2 - Suitable for use on flat or uneven surfaces in difficult conditions

Knee pads with the EN 14404 certification are further divided into types:

- Type 1 - Knee pads fixed around the leg and independent of other clothing.

- Type 2 - Knee pads made of foam or other padding fixed in the trousers’ knee pad pockets or as a permanent part of the trousers.

- Type 3 - Loose knee pads that are not fixed around the leg, but are removable.

- Type 4 - Knee pads that are part of another product.

See our full range of knee pads here.

EN 420 - Gloves

EN 420 is the standard for general requirements and test methods of gloves. Be aware that if the glove is damaged, protection is impaired. These gloves are not intended for use with fire.

EN 374 - Chemicals (gloves)

Gloves certified with EN 374 protect the user from chemicals and microorganisms. The gloves are categorised from A-L based on what they protect against:

A: Methanol

B: Acetone

C: Acetonitrile

D: Dichloromethane

E: Carbon disulphide

F: Toluene

G: Diethylamine

H: Tetrahydrofuran

I: Ethyl acetate

J: n-Heptane

K: Sodium hydroxide 40%

L: Su

In addition, they are categorised in levels from 1-6, based on the speed of penetration:

Level 1: Up To 10 minutes

Level 2: Up to 30 minutes

Level 3: Up To 60 Minutes

Level 4: Up to 120 minutes

Level 5: Up To 240 minutes

Level 6: Up to 480 minutes

EN 388 - Mechanical hazards (gloves)

Gloves certified with EN 388 protect against mechanical risks. This certification has been updated from version 2003 to 2016, where the gloves are exposed to new requirements and a new cut resistance test. Gloves certified according to EN388:2003 achieve an A-D score after the test, of which A: abrasion resistance, B: cut resistance, C: tear resistance and D: puncture resistance. The higher the score, the better. The highest score a glove can achieve is 4544.

Gloves certified according to EN 388: 2016 also achieve a score based on abrasion resistance, tear resistance and puncture resistance. The glove’s cutting resistance is indicated by a letter from A to F, of which F indicates the highest level of cutting resistance. Therefore, the highest score a glove can achieve here is 4444F.

Thermal risks (gloves)

EN 407 requires the gloves to be certified and approved for protection upon contact with high heat and fire, such as contact heat, radiant heat or molten metal. This certification is divided into levels of protection from a-f:

a: Fire

b: Contact heat

c: Convective heat

d: Radiant heat

e: Molten metal - small splashes

f: Molten metal - larger quantity

EN 511 - Cold (gloves)

EN 511 requires the gloves to be certified and approved for protection against cold. The glove must be able to withstand both penetrating cold (convective cold) and contact cold, i.e. through direct contact. It is not a requirement that the glove must also be tested against water penetration. The gloves must, as a minimum, be able to achieve level 1 protection according to the EN 388 standard when it comes to abrasion and tear resistance.

Read the glove guide on how to choose the right gloves.

See our full range of gloves here.

Leisure wear

EN 1150 - Visible leisure wear

This is the standard for high visibility clothing for non-work use. The standard is used for, for example, clothing for a walk in the dark or for children out cycling.

Do you need information regarding a certification?

You are always welcome to contact our customer service at info@cheap.workwear.com or tel. +45 9674 2030.